Solution For Intelligent Mines

Introduction

Based on the intelligent mine operating system platform (RED-MOS), the overall solution of Huaxia Tianxin Intelligent Mine aims at the construction of intelligent mine and its integrated intelligent management and control, and integrates artificial intelligence, industrial Internet of Things, cloud computing, big data, robots, 5G communications, intelligent equipment, etc. With modern coal mines. Intelligent system of comprehensive perception, real-time interconnection, analysis and decision-making, self-learning, dynamic prediction and collaborative control will be formed to realize the intelligent operation of safety production management processes such as development, mining, transportation, ventilation, safety assurance, equipment maintenance and operation management, and gradually form an intelligent mine centered on superior units, realizing the intelligent mine system of reducing personnel, improving efficiency, safety and health.

- Architecture diagram

- Construction content

- Related cases

Architecture diagram

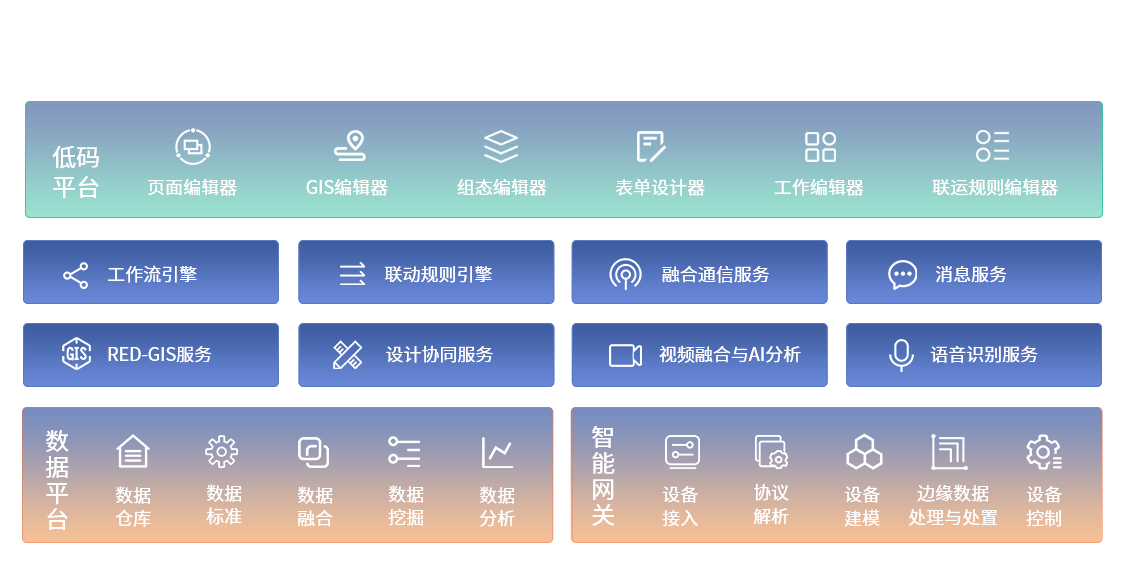

-

01应用层

-

02智能矿山操作系统

RED-MOS

-

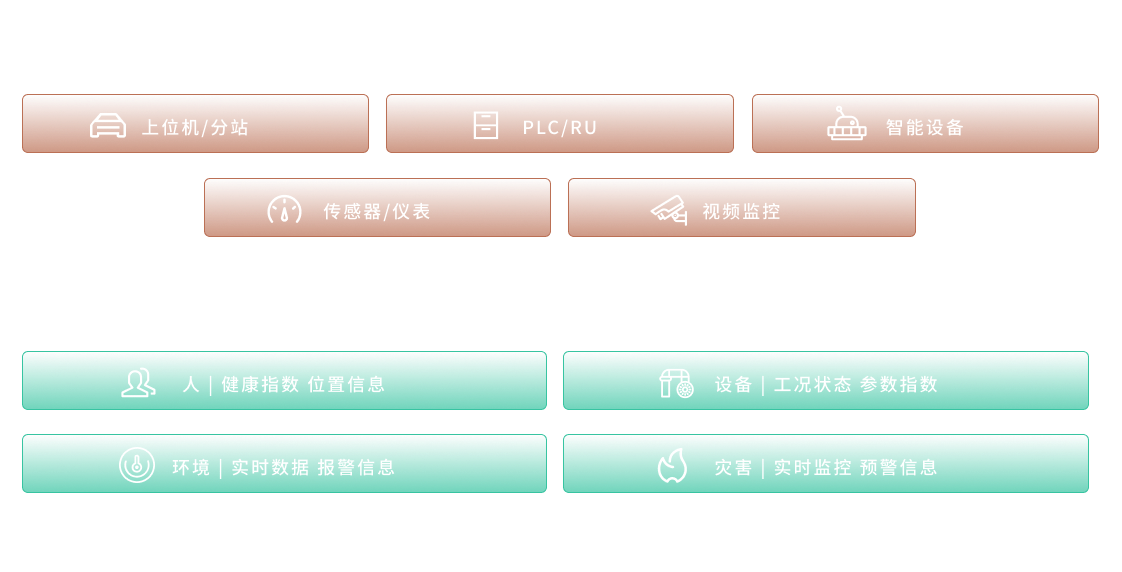

03基础设施层

-

04感知层

Construction content

Intelligent Coal Mine Information Infrastructure

Build network system and data center, open up data transmission and utilization channels, plan network and data security system in a unified way, ensure the security redundancy of internal and external transmission and utilization of information, at the same time, divide, isolate and connect production network, office network, fund data network and Internet, strengthen network and data security awareness, and actively promote regular network and information system level protection evaluation.

Intelligent Integrated Management and Control Platform

Based on the industrial Internet of Things platform of the intelligent mine operating system (RED-MOS®), an intelligent integrated management and control platform is built to integrate the data of various business systems and the data of the perception layer to form a complete intelligent system for mine perception, interconnection, analysis, prediction and decision-making, so as to realize the intelligent operation of the whole process of mine development, mining, transportation, washing, safety assurance and production management.

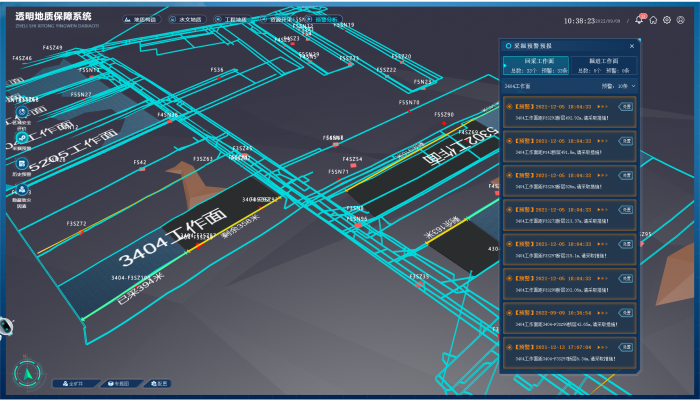

Intelligent Geological Guarantee System

Deep fusion of geological data and engineering data is carried out, and a high-precision fusion model of geological and engineering data updated in real time is established by means of geological data deduction, multiple reuse of geological data and intelligent update of geological data, so as to realize the transparency of mine geological information. Build application scenarios of new technologies and new equipment such as intelligent drilling, intelligent geophysical exploration and intelligent detection robot, and form a high-precision dynamic geological model based on static state and integrated with automatic update.

Intelligent Tunneling System

According to the geological conditions and technological requirements of mine tunneling, reasonable tunneling technology and equipment are determined according to local conditions, and efficient auxiliary operation systems are matched to gradually realize the parallel operation of tunneling and supporting. Encourage the application of advanced technologies and equipment such as intelligent detection, automatic orientation and navigation, automatic cutting and forming of roadway section, automatic anchoring, efficient dust removal, etc., so that the production system of the heading face has the functions of intelligent perception, autonomous decision-making and automatic control, so as to realize the efficient cooperative operation of the system with few or no people at the heading face.

Intelligent Fully Mechanized Mining System

The equipment and system of fully mechanized mining face are integrated into the same data monitoring and control platform, the system database is constructed, the data sharing of each system is realized, the integrated control of each system is carried out through industrial Ethernet and field control bus, and the continuous and efficient operation of fully mechanized mining equipment is realized on the basis of seamless data connection, to achieve intelligent coal mining, production automation, management informatization and digitalization of fully mechanized coal mining face, realize automatic coal mining, realize "automation" and "fewer people" of fully mechanized coal mining face, and achieve the automatic production mode of "automatic control of working face as the main, manual intervention as the supplement, remote real-time monitoring and command". At the same time, the system analyzes the operation data of the relevant equipment of the fully mechanized mining face, predicts and prevents the potential hazards, improves the normal rate and operation rate of the equipment, and realizes safe and efficient production.

Main Coal Flow Transportation System

A mine for main coal flow transportation based on a belt conveyor, it can build a main coal flow system with the functions of single machine automatic control, multi-machine collaborative linkage, remote centralized control, coal quantity automatic balance, belt intelligent speed regulation, dust concentration detection and automatic spray dust suppression, operation condition detection and fault intelligent early warning. Based on AI coal quantity intelligent identification, it has personnel illegal operation intelligent monitoring, large coal/coal pile/foreign body identification and early warning functions, realizing the intelligent transportation of belt conveyor.

Intelligent Auxiliary Transportation System

Based on the accurate positioning information of vehicles, the intelligent scheduling management of auxiliary vehicles with intelligent planning and task allocation functions is established to realize the intelligent control, intelligent path planning and intelligent scheduling of auxiliary transport vehicles such as material transport and personnel transport.

Integrated Support System

Construct intelligent systems for auxiliary production processes such as ventilation, power supply, compressed air, lifting, drainage and extraction, so as to realize unattended underground central substation and mining area substation, one-key start and stop of mine main ventilator, remote control, remote centralized control of fixed drainage operation, central water pump house and unattended mining area sump.

Intelligent Safety Management and Control System

According to the geological conditions and production conditions of the mine, build and improve the dual prevention mechanism of safety risk classification management and control and hidden danger investigation and management, realize the comprehensive, intelligent and dynamic management and control of safety risks, and build underground integrated communication, integrated prevention and control system and supporting equipment. Realizing the load bearing of coal mine safety monitoring system, personnel positioning management system, communication and liaison system, intelligent video analysis system, intelligent ventilation system, power supply monitoring system, rock burst monitoring system, hydrological monitoring system, mine pressure monitoring system and other systems, and realizing the full data integration and intelligent analysis of human, machine, environment and management. It has the functions of intelligent evaluation and identification of safety risks, emergency disposal of major safety incidents, disaster risk monitoring and early warning, intelligent analysis and simulation, emergency rescue auxiliary command, accident cause analysis, and intelligent planning of disaster avoidance routes under the state of mine disaster.

Intelligent Operation Management System

Establish a unified intelligent operation and management system, including digital decision-making system, equipment life cycle management system, plan management and cost control, support the comprehensive integration of various business applications of the coal mine, break through the management island and data island, and realize the intelligent operation and management of "integration of human, finance and property, integration of production, transportation and sales, and comprehensive interconnection of business".

Intelligent Park

Integrate the business systems of the park, such as fire protection, security, parking, visitors, conference management, attendance, shopping and restaurants, to form an intelligent park management and control system with comprehensive perception, real-time interconnection, analysis and decision-making, autonomous learning, dynamic prediction and collaborative control.

Beijing Public Network Security File No.11010502054023

Beijing Public Network Security File No.11010502054023