Solution For Intelligent Coal Preparation Plants

Introduction

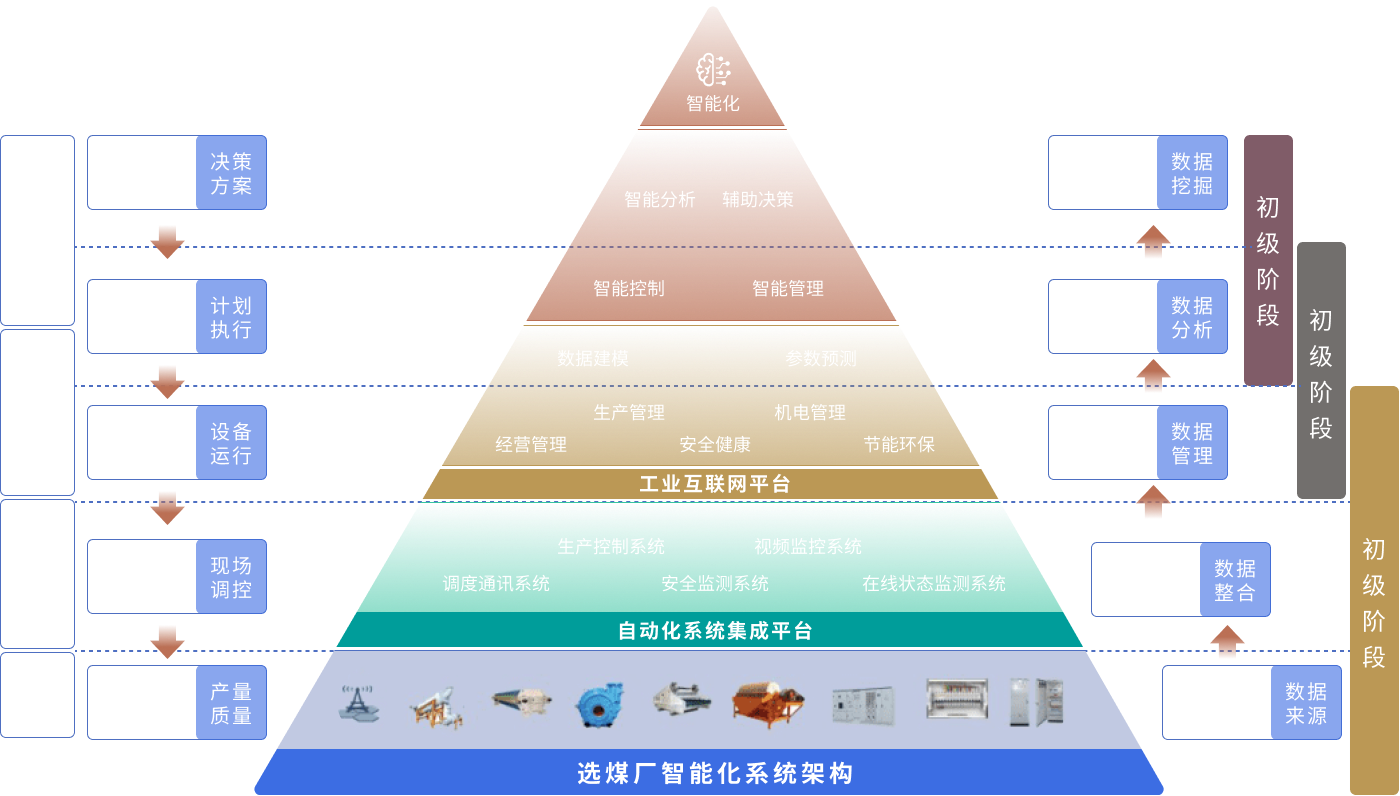

The overall solution of Huaxia Tianxin Intelligent Coal Preparation Plant is based on the Intelligent Mine Operating System Platform (RED-MOS®), which integrates production, operation, safety, operation and maintenance into the intelligent management and control system by means of diversified data acquisition methods, using technologies such as interconnection, Internet of Things, data, cloud computing and intelligence. It realizes the intelligent management and control of basic information management and production process, improve management efficiency, reduce prediction and increase economic benefits, and finally, a safe, efficient, green and comfortable humanized intelligent coal preparation plant will be built. The construction of intelligent coal preparation plant mainly includes infrastructure construction (including plant network, equipment and facilities, basic software), basic automation, intelligent control, intelligent management system, intelligent decision-making, information security, management system and other aspects, each of which includes many subsystems.

- Architecture diagram

- Construction content

- Related cases

Architecture diagram

Construction content

Basic Platform Construction

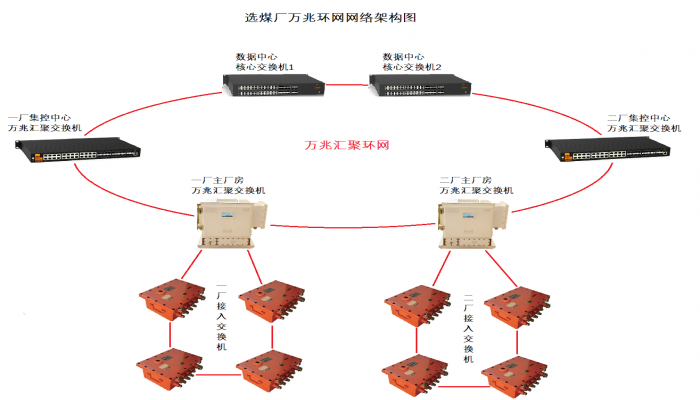

Construction of coal preparation plant data center, modular machine room, 10-Gigabit industrial ring network, cloud platform, integrated management and control software platform, expert database platform, etc.

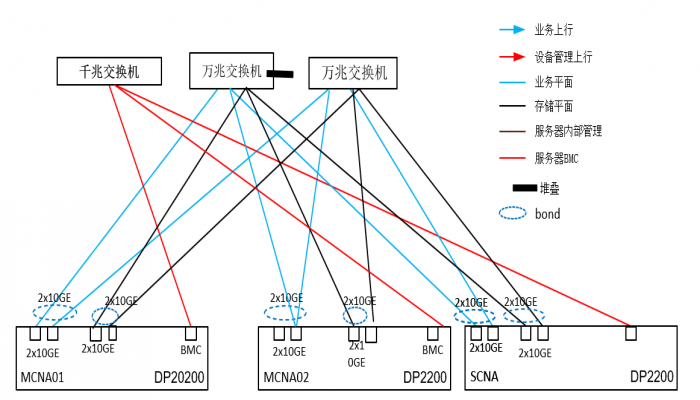

Data Center

Take each node is configured with 2xGE + 4x10GE (minimum 2xGE + 2x10GE) network cards for example. Two GEs are used for management, two 10GEs are used for storage, and two 10GEs are used for service. The BMC of each node is connected to the switch through a network cable. The corresponding interface of the switch is configured with a GE electrical interface module. A pair of 10GE switches are stacked by 2x40GE to provide 4 x10GE/GE interfaces externally.

Construction of Industrial Ring Network

Comprehensive Management and Control Platform and Expert Knowledge Base

Establish a comprehensive portal of the coal preparation plant to support relevant personnel to select and click to enter the functional areas of different business management requirements after logging in the system, covering production management, electromechanical management, safety management, production control platform, expert knowledge base, thematic analysis and other summary information. It also provides functional menus such as production management, electromechanical management, safety management, production control platform, expert knowledge base and thematic analysis on the intelligent management module, and directly enters the corresponding functional module by clicking. At the same time, it has the functions of to-do tasks, sending and receiving emails, message notification, document news and so on. Realize collaborative office. Establish an expert knowledge base based on various coal preparation algorithms, curve drawing methods, analysis and evaluation methods, electromechanical management, expert experience in production management and process control.

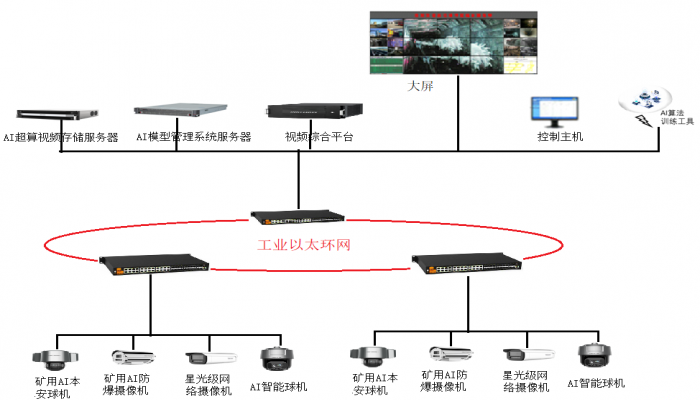

Video Surveillance and Video AI analysis

The intelligent video AI analysis system can access video streams such as mainstream brand cameras, hard disk video recorders and streaming media servers for AI analysis. Once there are hidden dangers in the monitoring points, the platform can receive the results of hidden danger analysis and report them in time, so as to solve the problems that the production enterprises can not find hidden dangers in time by supervisors, and there is no evidence for accountability. Meet the high requirements and strong standards of the enterprise for safety production.

Basic Automation Construction

Carry out automation and intelligent transformation for each production process to realize unmanned, intelligent, centralized control, intelligent environmental monitoring, intelligent equipment online monitoring, intelligent video online AI analysis and linkage, etc.

Intelligent Screening

Realizing real-time data monitoring of raw coal washing rate and real-time monitoring of storage conditions, as well as online monitoring of belt conveyor, crusher and other high-power and key equipment, through the judgment and prediction of equipment status

Dense Medium Separation

The dense medium separation process is the core link of coal preparation, and is also an important guarantee to ensure the product quality and improve the economic benefits. The intelligent construction of the coal preparation plant must start from the core link to realize the substantial improvement of the economic benefits. The intelligent platform software + ash analyzer detection is used to realize the stability of the washing density, the interlocking of the product index control, the stability of the product index and the improvement of the product recovery rate.

Coarse Slime Separation

Carry out online monitoring and visualization of the whole process of coarse slime separation, including particle size composition, separation feed concentration, flow, clean coal ash, tailings ash, separation bed density and other information.

Intelligent Flotation

Real-time detection of flotation reagent dosage, flotation concentration, flow, coal slime particle size, effective foam layer thickness, flotation concentrate ash, tailings concentration and ash, combined with feed properties and product indicators, establish flotation dosing data model, and independently predict flotation link dosage, dosing ratio, aeration, clean coal or tailings ash and other process parameters.

Intelligent Concentration

In the process of thickening and dosing, the multi-process parameters of the coal slime sedimentation of the thickener are monitored and analyzed, the mathematical model of thickening and dosing is established according to the real-time historical parameters, the given dosage of the flocculant is predicted in combination with the feeding properties, and the dosage concentration and dosage of the flocculant are adjusted in real time according to the sedimentation effect of the coal slime water. The self-learning function of online data is used to realize the pre-judgment control and automatic optimization of dosing amount in the concentration link, and finally realize the effective concentration of slime water in the concentration process link. The control mode of concentration dosing is divided into equipment monitoring mode and logic regulation mode.

Intelligent Pressure Filtration

In the process of pressure filtration and dehydration, intelligent control links are established from the aspects of feeding bucket of pressure filtration system, feeding of pressure filtration machine, discharging of pressure filtration machine, system safety locking, etc., and a multi-level process intelligent control system is established. In this system, each control link has different functions and scope of action, not only to deal with the behavior of each intelligent control logic related to control, maintenance and management. At the same time, it shall be responsible for the coordination and cooperation among the units in the distributed environment to ensure the automatic control of a single filter press and the overall production of multiple filter presses, so as to improve the intelligent level of each link, improve the work efficiency, reduce the demand for post personnel and reduce the labor intensity. The intelligent filter press system is divided into two types: equipment status mode and control logic mode.

Intelligent Loading

It includes the monitoring of train shipment and truck shipment, which is upgraded on the basis of the original station. First of all, it is necessary to ensure that all functions of the original station are normal. Then, by adding software and hardware such as train number identification, carriage positioning, chute positioning, chute control algorithm, etc., the existing hardware system for rapid quantitative loading and PLC control system are retained. These new systems replace the manual observation, judgment, operation and other execution functions, and complete the loading task under the unified command of the server.

Personnel Positioning

Realizes intuitive understanding of personnel location and historical track of personnel, so that managers can quickly deploy personnel according to the location. Through the positioning module, they can intuitively understand the location of personnel in the plant, whether they are in a dangerous position or whether they are in the post area. At the same time, they can understand the path of personnel through the historical track.

Construction of Intelligent Control and Management Decision

Integrate and optimize each process flow, for example: Heavy medium, concentration, pressure filtration, loading, coal leveling, intelligent start and stop, etc., as well as management decision analysis, prediction and early warning. Based on the framework system of intelligent platform, a unified production command and control platform is established according to the production dispatching and command of the coal preparation plant. Integrate and integrate the data of safety, production, electromechanical management, production centralized control, safety monitoring, video surveillance and other production auxiliary subsystems in the existing and infrastructure of the coal preparation plant and the intelligent upgrading project of the production system, so as to realize data sharing and information fusion among the subsystems and conduct comprehensive display, as well as the unified dispatching, command and management of the coal preparation plant. According to the national and industrial standards and regulations, the comprehensive analysis of the production process is carried out, the advancement of the product indicators and control parameters and the rationality of the process are comprehensively evaluated, and the optimization solutions are given for the existing problems. It mainly includes the analysis of the production situation, the analysis of the operation situation and the evaluation of the process effect. Production index prediction, product structure optimization, economic benefit prediction, equipment operation analysis, production organization decision, comprehensive auxiliary decision, statistical analysis of different management levels, different management leadership cockpit, etc., to meet the decision data support of safety production management of coal preparation plant.

Construction of Digital Twin Coal Washing Plant, Mobile Management Platform and Integrated Management and Control Platform

The digital twin intelligent monitoring platform uses oblique photography, BIM and simulation technology to carry out high-precision three-dimensional modeling for the industrial square, washing plant and washing equipment of the coal preparation plant, and displays the scene structure, equipment layout, process flow, monitoring and control in the coal preparation plant in the form of three-dimensional visualization. The process flow display module of the coal preparation plant is based on the workshop equipment layout and equipment contact diagram. The high-precision three-dimensional modeling technology is used to effectively ensure the accuracy of the process flow. The system provides the simulation of several important coal preparation processes including clean coal, middling, gangue, etc. Users can select any production process. The system will automatically match the visual angle and display the main functions of the equipment used in the current process with the change of coal flow and the explanation of voice subtitles. The platform constructs a highly visual and immersive virtual reality environment for the coal preparation plant, dynamically simulates the actual coal preparation process in the three-dimensional scene, and presents the scene of "invisible, immovable and difficult to reproduce" to the user through the 3D helmet. Users can interact with the equipment in the scene, disassemble and teach the key equipment, so that users can master the working principle of the equipment, experience and learn the coal preparation process in a safe environment, so as to effectively improve the training efficiency and reduce the training cost. The platform integrates the production and safety information of the coal preparation plant, including current or cumulative information such as output, sales volume, power consumption, hidden dangers, risks, three violations, etc. Users can intuitively understand the current safety production situation of the coal preparation plant through the home page of the system, and help leaders to command and make decisions.

Beijing Public Network Security File No.11010502054023

Beijing Public Network Security File No.11010502054023